In this blog post, we present a remarkable case study conducted by Celera, a high-tech company specializing in thermal management solutions for electronic devices and components. The case focuses on the use of Simcenter FLOEFD technology to accurately simulate temperature and heat flow in high-power LED lighting. We will reproduce the executive summary and key findings from the original case written by Norbert Arthur Frauz, Engineering Coordinator at Celera. The study showcases Celera's expertise in leveraging advanced simulation tools and precise measurements to provide innovative thermal management consulting services to various industrial sectors.

Celera:

Celera is a leading high-tech company that specializes in providing thermal management solutions for electronic devices and components across multiple industries. By utilizing advanced technologies such as Simcenter FLOEFD software, Celera accurately simulates temperature distribution and heat flow, enabling the identification of potential issues and the development of effective solutions. With a strong focus on customer satisfaction, Celera offers specialized technical support and high-quality products to renowned companies worldwide.

About the author:

Norbert Arthur Frauz is the Engineering Coordinator at Celera. He is a Control and Automation Engineer, specialized in Fluids and Thermodynamics. Norbert is responsible for coordinating technical and innovation projects, with extensive knowledge in CFD simulations applied to semiconductors and high-power LED luminaires, with a focus on natural convection heat dissipation.

Thermal Simulations in the LED Lighting Industry

Simulating beyond thermal properties – material properties and semiconductor calibrations

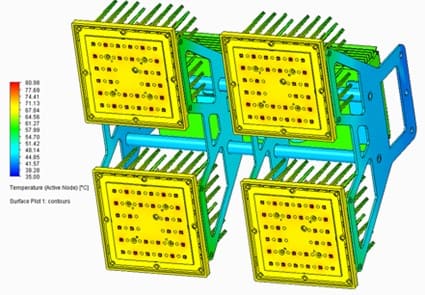

Executive Summary Celera uses Simcenter FLOEFD technology to accurately simulate the temperature at the LED junction and the heat spread over the components that make up the luminaire. The company also uses advanced characterization equipment, Simcenter T3STER and TerraLed, to improve the accuracy of CFD simulations of electronic components. These tools enable Celera to offer high-tech thermal management consulting services to various industrial sectors, providing specialized technical support and high-quality products Norbert Arthur Frauz Engineering Coordinator at Celera

Introduction

At Celera, we provide thermal management solutions for various industries, including high-power LED lighting.

Celera

Celera is a high-tech company that provides thermal management solutions for electronic devices and components in various industries, including the high-power LED lighting industry. Using advanced technology such as Simcenter FLOEFD software, Celera is able to accurately simulate temperature and heat flow in electronic components, allowing it to identify problems and provide effective solutions to ensure optimal performance and durability of these components. The company serves several leading companies in their respective industries in various countries, offering specialized technical support and high-quality products above market average.

High-Power LEDs

By using the FLOEFD software in conjunction with the precision of the results measured by Celera, we were able to identify a problem in an LED luminaire for horticulture that was causing the polycarbonate lens to burn out. Through thermal and fluid dynamics simulations conducted with FLOEFD and precise measurements using T3ster and TerraLed equipment, we were able to understand the behavior of the LED luminaire and identify the root cause of the problem.

Simulations, results and tools

Initially, it was thought that the problem was related to the excess heat generated by the LEDs. However, after characterizing the LEDs in the equipment, setting up the luminaire in the CFD (digital twin) software, and analyzing the simulation results, it was identified that the cause of the lens burnout was the cascade effect that occurred due to the absorption of a portion of the blue spectrum emitted by the LEDs by the polycarbonate lens. This led to a degradation process, which decreased its transparency, and consequently, more thermal energy was absorbed from the beam of light, leading to the carbonization of the lens and subsequent burning of the LEDs.

Through this detailed simulation, which took into account not only electrical aspects but also material properties and photometric properties, it was possible to identify the real problem and find a solution to improve the LED luminaire, thus avoiding losses and customer dissatisfaction. Our client (Audax) sent us some luminaires so that we could measure the temperature at the LED junction after thermal stabilization. These luminaires underwent tests, and each of the blue, white, and red LEDs was individually monitored so that their maximum temperatures could be known, as seen in the photo.

Additionally, each type of LED was tested in the TerraLed integrating sphere to determine its luminous efficiency, heat generation, and junction resistance up to the base of the printed circuit board.

In these initial measurements, we already noticed that the junction temperatures were not very high and by themselves would not lead to lens melting. With these data obtained from empirical laboratory measurements, we characterized the FLOEFD simulation. Upon analyzing the simulation results, it was found that the simulation was faithfully representing the real luminaire operation, and that the temperatures in the luminaire were within a safe operating range.

We then contacted the manufacturer of the polycarbonate lenses to obtain more information on the lens absorption properties. With these new curves, we characterized the material in the software and configured the wavelengths emitted by each of the LEDs and re-simulated. This time, the result was entirely different, and already during the simulation stabilization, the software informed us that the lens was melting. Upon analyzing the results, we saw that the lens was subjected to much higher temperatures than it could withstand, but not from the base of the LEDs, rather absorbed from the beam of light.

Factors that affect the analyses

The analyses performed with FLOEFD take into account various factors, including product geometry, operating conditions, materials, and thermal properties. These factors directly affect the flow and heat transfer conditions, which can be analyzed with FLOEFD. For example, in a luminaires analysis, the geometry and materials of the luminaire can affect temperature distribution and condensation/ice formation. Operating conditions, such as ambient temperature and luminaire power, also directly affect these results.

Results and objectives of the analyses

The results of the analyses performed with FLOEFD include detailed information about product performance, including flow, temperature, and heat transfer. These results can be used to optimize product design, improve energy efficiency, and ensure that the product meets regulatory and safety requirements. The objectives of the analyses include reducing product development time, improving product quality, and reducing prototyping and testing costs. Additionally, analyses performed with FLOEFD help increase confidence in product design, reducing the risk of failures and performance issues.

FLOEFD is a computationally efficient and easy-to-use computational fluid dynamics simulation technology. It allows engineers to perform advanced fluid and heat transfer analyses directly in CAD, helping to quickly identify design issues and reduce product development time. With FLOEFD , flow, heat transfer, and fluid mechanics analyses can be performed in a wide range of applications, from luminaires and automotive electronics to gas turbines. |

Conclusion

We have been using FLOEFD tools for several years, and their importance in helping our clients develop better and faster projects continues to grow. In the case mentioned above, by using these solutions together, we were able to identify a very specific problem that would probably not have been found otherwise.

Based on this data, Celera was able to help the client develop more efficient and secure solutions, such as replacing the lens material and adding a graphite mat to improve thermal contact between the printed circuit board and the heat sink. These solutions allowed for a significant reduction in the risk of premature LED failure, ensuring greater durability and reliability of the final product.

In addition, the use of FLOEFD also enabled a significant improvement in the luminous efficiency of LED luminaires. With the results obtained from simulations, CELERA was able to optimize the optical system design of the luminaires, increasing the intensity of the emitted light and reducing light loss. This improvement resulted in greater energy efficiency of the luminaires, providing energy savings for end users. In summary, the studies carried out with FLOEFD allowed CELERA to develop more efficient, safe, and reliable products, adding value to its customers and to the market.

About the author

Norbert Arthur Frauz. Engineering Coordinator at Celera, Control and Automation Engineer, Specialist in Fluid and Thermodynamics, Coordinator of Technical and Innovation Projects, with extensive knowledge in CFD simulations applied to semiconductors and high-power LED luminaires and with dissipation by natural convection.

References:

CELERA Fibras “http://www.celerafibras.com.br/", Campinas SP Brazil, 2023.

ASTM International "ASTM D5470-12, Standard test method for thermal transmission properties of thin thermally conductive solid" Philadelphia PA USA, 2012.

Clemens J. M. Lasance and András Poppe, "Thermal Management for LED Applications" Springer, New York NY USA, 2014.

Frank Incropera and David DeWitt, "Fundamentals of Heat and Mass Transfer", 4th Edition, Wiley, New York NY USA, 1996.

Sign up below to access our newsletter and receive the PDF of the case (in English).

Like it and want to know more about it? Be sure to check out our complete material on Simcenter FLOEFD. Schedule a meeting with us now to learn more about CAE and how we can help you succeed!

Comments